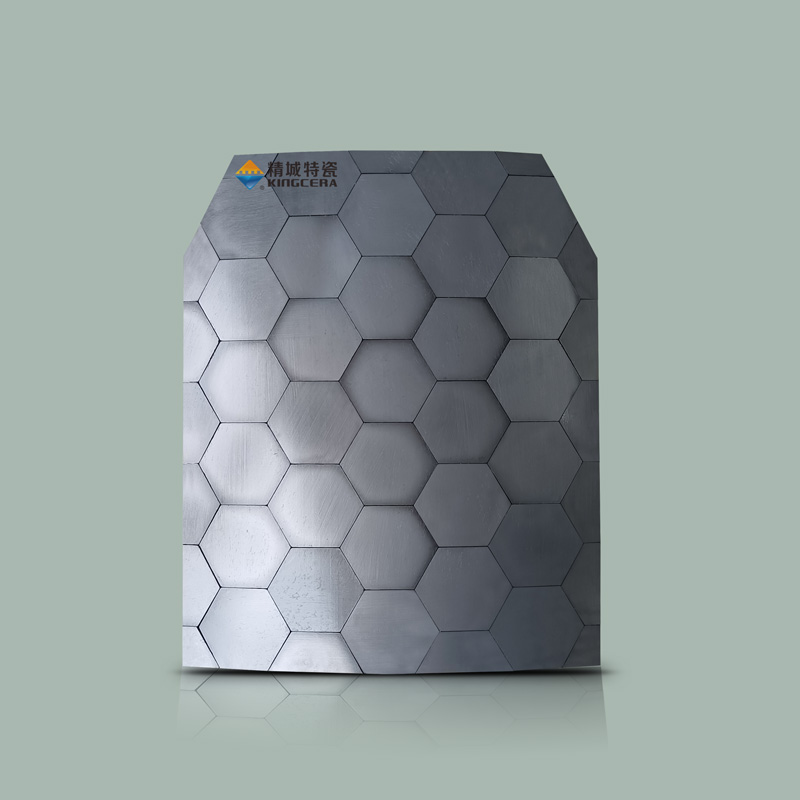

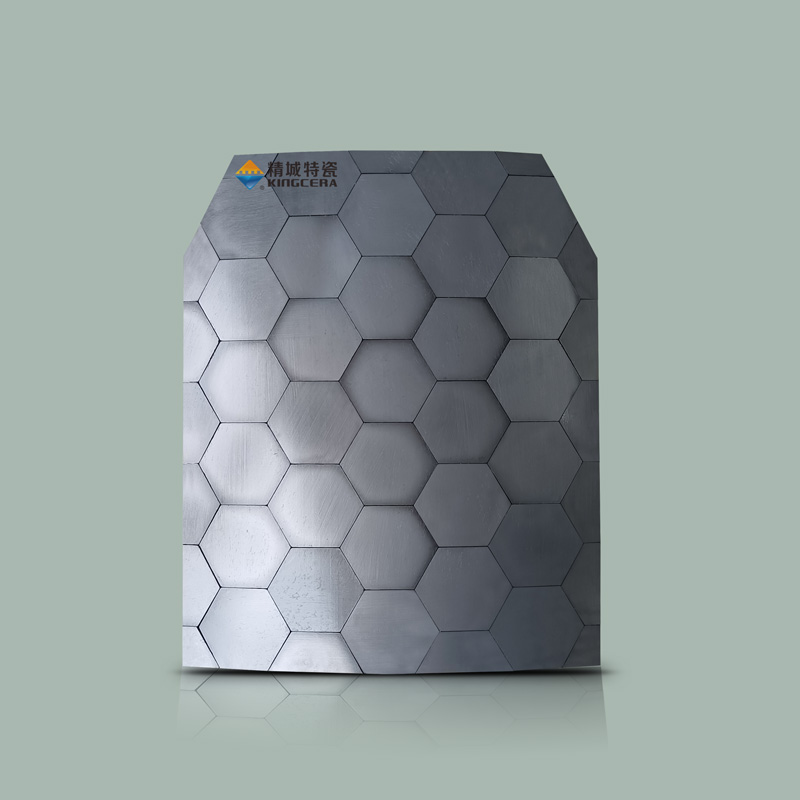

Ceramic bulletproof, as an important part of the field of bulletproof, it has many special advantages that metal does not have. Ceramic bulletproof relies on its high specific stiffness, high specific strength and chemical inertness in many environments. It is better than metal because, in the resistance to the impact of the bullet, metal material will produce plastic deformation and absorb energy, while ceramic almost does not produce plastic deformation, and passivates or even breaks the warhead relying on its own high strength and high hardness characteristics. The surface of the ceramic pulverized. At the same time the formation of small and hard fragments occurs in the process of absorbing the energy of the high-speed warhead. As a result, the bullet-proof effect is excellent.

In bulletproof ceramics, the common bulletproof materials are aluminum oxide, silicon carbide, boron carbide, etc., but in these materials, aluminum oxide ceramics are favored, which is why?

The price is low: Alumina bulletproof ceramics are slightly more expensive than metal bulletproof materials, but its performance is far better than metal materials. Compared with silicon carbide and boron carbide, its price is very cheap. In comprehensive consideration of the cost of various materials and other properties such as stiffness, and as far as possible to ensure that the bullet-proof performance meets the specified requirements under the condition of making the cost as low as possible, alumina bulletproof ceramics are favored.

Strong bulletproof ability: the main component of alumina ceramics is α-alumina, its chemical stability, high hardness, will not reduce the performance in high temperature, oxidation and other circumstances. It can smash the warhead with high hardness and absorb the energy of the warhead, to achieve the purpose of bulletproof. The bullet-proof grade reaches the American standard 4, which can meet most of the bullet-proof requirements.

Light weight: in the same area, the quality of alumina bulletproof ceramics is more than 50% lighter than that of metal bulletproof materials, which greatly reduces the load of soldiers and armored vehicles.

There are many types of aluminum oxide bulletproof ceramics: 85, 88, 90, 92, 95, 99 and other types, the price and performance are not the same, and the option is more.

The alumina process is simple and mature, and the product stability is good: compared with silicon carbide, boron carbide and other materials, the processing process of alumina is relatively simple, and the process is mature. The performance and size of the alumina bulletproof sheet are more stable.

The material choice of bulletproof sheet is a process of comprehensive consideration of various factors. In the comprehensive comparison of the above factors, alumina ceramic bulletproof has become an ideal choice for many civilian bulletproof fields.

KINGCERA