Description: The monololithic plate silicon carbide ceramic is different from the bulletproof plate of small pieces of ceramic splicing, such as 250×300 insert board, which uses a whole piece of ceramic as an energy-absorbing material to block bullet impact. The advantage is that there is no gap in the ceramic surface, and the viscosity between the fiber material is stronger, the overall protection effect is better, and the performance of resisting multiple bullets is better. Reaction-sintered silicon carbide plate and non-pressure sintered silicon carbide plate are two kinds of plate production process, and each has its advantages and disadvantages.

I.Sintering method

Silicon carbide (SiC) ceramics is a kind of high performance ceramic material, which has a wide range of applications. Sintering is an important step in the preparation of SIC ceramics. It is mainly divided into non-pressure sintering, atmosphere sintering, hot press sintering, microwave sintering, reaction sintering, hot isostatic sintering, discharge plasma sintering, melt impregnation method and hydrothermal method. These technologies can promote the densification of SIC ceramics and reduce the sintering temperature, thus improving the performance and stability of the material.

The sintering process of non-pressure sintering silicon carbide is divided into dry pressing forming and the followinng 3 stages: drying, pre-firing and sintering.

step 1. Dry press molding

The matching material is put into the mold and pressed into shape by a special pressure device. The formed body needs to maintain a certain strength and toughness to avoid cracking in the subsequent processing.

Step 2.Dry

The molded body is placed in the oven for drying to remove the moisture and volatiles inside and on the surface, making it more suitable for sintering.

step 3. Pre-firing and sintering

The dried body is put into the sintering furnace, and it is heated to reach a certain temperature and atmosphere conditions for sintering. In the sintering process, it is necessary to control the appropriate temperature, time and sintering atmosphere to ensure the density and stability of the sintered body. After sintering, it is necessary to carry out cooling, cutting, grinding and other processing.

Reaction-sintered silicon carbide is a kind of ceramic material prepared by mixing silicon powder and carbon powder and then reacting at high temperature. Reaction silicon carbide is usually made at a lower temperature, through a chemical reaction to penetrate free silicon into silicon carbide, without any shrinkage deformation in the sintering process. Reaction silicon carbide is suitable for the making of various shapes and sizes of silicon carbide ceramic products, including complex shape parts and large size products. Furthermore, reaction silicon carbide is mainly used in aerospace, electronics, semiconductors and other fields, as high temperature structural material and chemical corrosion resistant material.

II. Physical properties

Silicon carbide ceramics have excellent high temperature resistance, corrosion resistance, wear resistance and other properties, and are widely used in aerospace, automotive, energy, chemical and other fields. Because it has excellent mechanical properties, oxidation resistance, wear resistance and low friction coefficient, in addition to its good thermal stability, small thermal expansion coefficient, good thermal conductivity, thermal shock resistance and chemical corrosion resistance, it has been favored by military experts in various countries, and is widely used in different conditions.

III. Bulletproof principle

The basic principle of personal protection and armor protection is to dissipate the energy of the bullet, slow it down, and render it harmless. Most traditional engineering materials, such as metal materials, absorb energy through the plastic deformation of the structure, while ceramic materials absorb energy through the micro-crushing process.

The energy absorption process of silicon carbide bulletproof ceramics can be roughly divided into three stages:

(1) Initial impact stage: the bullet hits the ceramic surface, which blunts the bullet, and absorbs energy during the process of bullet crushing the ceramic surface to form a small and hard fragment area;

(2) Erosion stage: the blunted bullet continues to erode the fragment area, forming a continuous layer of ceramic fragments;

(3) Deformation, crack and fracture stage: Finally, tensile stress in the ceramic cracks, and then the backplane deforms, and the remaining energy is absorbed by the deformation of the backplane material. When the bullet hits the ceramic, both the bullet and the ceramic are damaged.

IV. Performance parameters of Kingcera non-pressure sintered silicon carbide ceramics

|

Project |

Unit |

Carbide(SiC) |

|

Silicon Carbide raw material purity |

% |

≥99 |

|

Density |

g/cm³ |

3.10 ~3.15 |

|

hardness |

HV0.5 |

≥2600 |

|

bending strength |

Mpa |

≥400 |

|

Elastic modulus |

Gpa |

400 |

|

Thermal conductivity |

W/(m•K) |

30~110 |

|

Temperature resistance |

℃ |

1600 |

|

Compressive strength |

Mpa |

≥2200 |

|

Thermal expansion coefficient |

1E-6/K |

4.0 |

|

Apparent porosity |

% |

<0.2 |

V. Application

Silicon carbide ceramics, using its special physical properties, shine in the field of bulletproof, and especially non-pressure sintered silicon carbide ceramics has become a very popular bulletproof material. Because of its small density and light weight, it has obvious advantages in bullet-proof equipment for individual soldiers, and is mostly used in bullet-proof jacket lining or single-defense inserts, and can also be used in protective devices for tanks and armored vehicles.

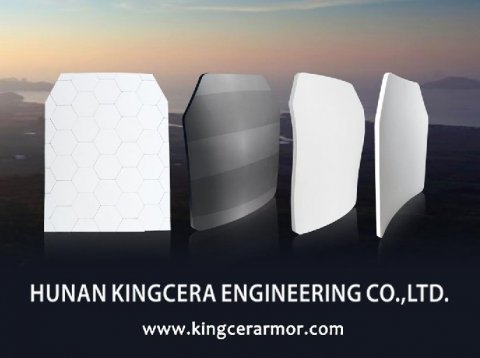

VI. Product display

.jpg)

.jpg)

-lp.jpg)